HYGROPHIL HCDT has been designed especially for the field of natural gas. As the materials that are applied are of very high quality, the sensors are extremely robust.

The humidity sensor, type L166x, consists of a robust multilayer of optically high and low refractive layers connected to the evaluation unit via two fiber-optic cables. Due to the special coating, light coupled into the sensor is changed in the spectrum, depending on the humidity. An integrated PT100 allows a temperature-compensated measurement.

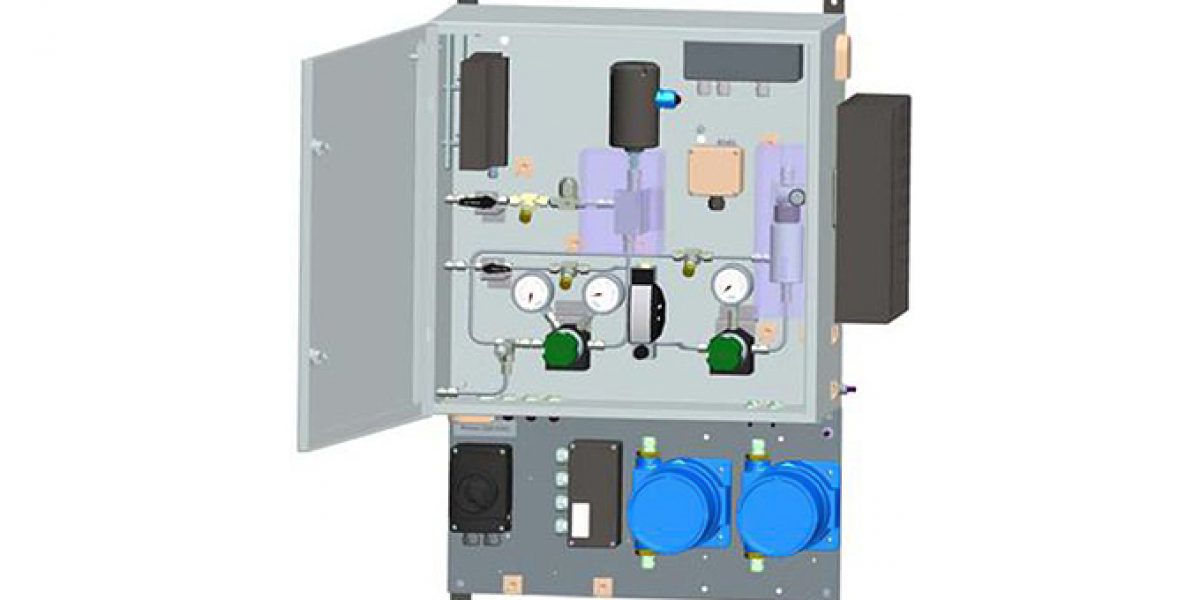

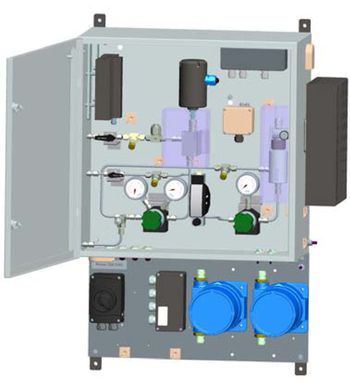

The HCDT sensor type 1510-11 works according to the dewpoint mirror principle, based on the new method of total internal reflection. As the pressure can be adjusted, the sample system type 5985-7x/-8x/9x allows to measure the hydrocarbon condensation at the cricondentherm point under constant gas flow.

- Determination of hydrocarbon dewpoint

- Measurement of trace humidity in gases

- Combined humidity and temperature sensor

- Application of sample conditioning System in explosive areas (zone 1)

- Maintenance-free and long-term stable

Application

Hygrophil HCDT combines the established water dewpoint measurement and the hydrocarbon dewpoint sensor to detect the moister content, the temperature and the hydrocarbon dewpoint of the measured medium. Apart from the very robust construction of the sensors, it is the measuring method itself that provides a number of decisive advantages.

Some advantages of this measurement principle protected by patents are:

- High measuring certainty including precision, reproducibility and low hysteresis

- Long-term stability of sensors

- Measurement of HCDT at the cricondentherm point (pressure reduction)

- Measurement of DT on high pressure side (pressure dewpoint!)

- Application in explosive area

- Simple installation (standardized connections)