| Flow Capacity L/min | |||

| Ambient Temp. (°F) | 77° | 90° | 105° |

| 12% H20 Vol. | 6 l/m | 5 l/m | 2.8 l/m |

| 15% H20 Vol. | 5 l/m | 4 l/m | 2.4 l/m |

| 30% H20 Vol. | 2.8 l/m | 2 l/m | 1.2 l/m |

| 50% H20 Vol. | 1.4 l/m | 1 l/m | 0.6 l/m |

| Exit Dew Point (°C) | 4 | 4 | 4 |

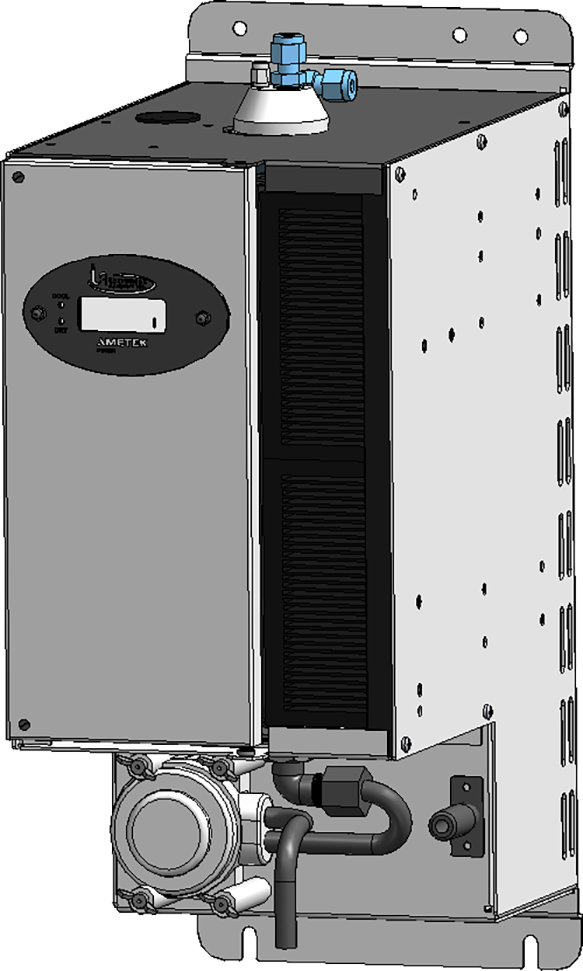

The Universal Analyzers 3000 series Thermoelectric Gas Cooler’s are widely used in both General Purpose and Electrically Hazardous Classified Areas such as those found at Refineries and Petrochemical plants. These gas coolers are used primarily in a gas analysis system to reduce a gas sample’s dew point providing a dry gas sample to one or more downstream gas analyzers. Its chasis design allows the 3000 Series to be optionally equipped with many sample system features that can be attached directly to the gas coolers enclosure. These features can include a sample pump, peristaltic pump, inline filter with condensate carry over sensor and a flow meter. With our FM/CSA/ATEX approvals, the series 3000 can be installed confidently worldwide.

In order to analyze combustion products or incinerator effluents utilizing a direct extractive sampling technique, it is important to remove the water vapor without removing the water soluble fraction(s) from the gas sample. The 3000 Series uses Peltier elements to Thermo Electrically chill and reduce the dew point of a gas sample to rapidly condense and remove the water, providing a dry gas sample for the gas analyzers.

The heat exchangers used in the Universal Analyzers gas sample coolers are designed to minimize the gas/condensate area and time of contact. This design will reduce to a minimum, the amount of mass transfer of those water soluble components from the gas phase into the liquid phase. The result is a dry gas sample which has the same composition on a dry basis before and after passing through the chiller.