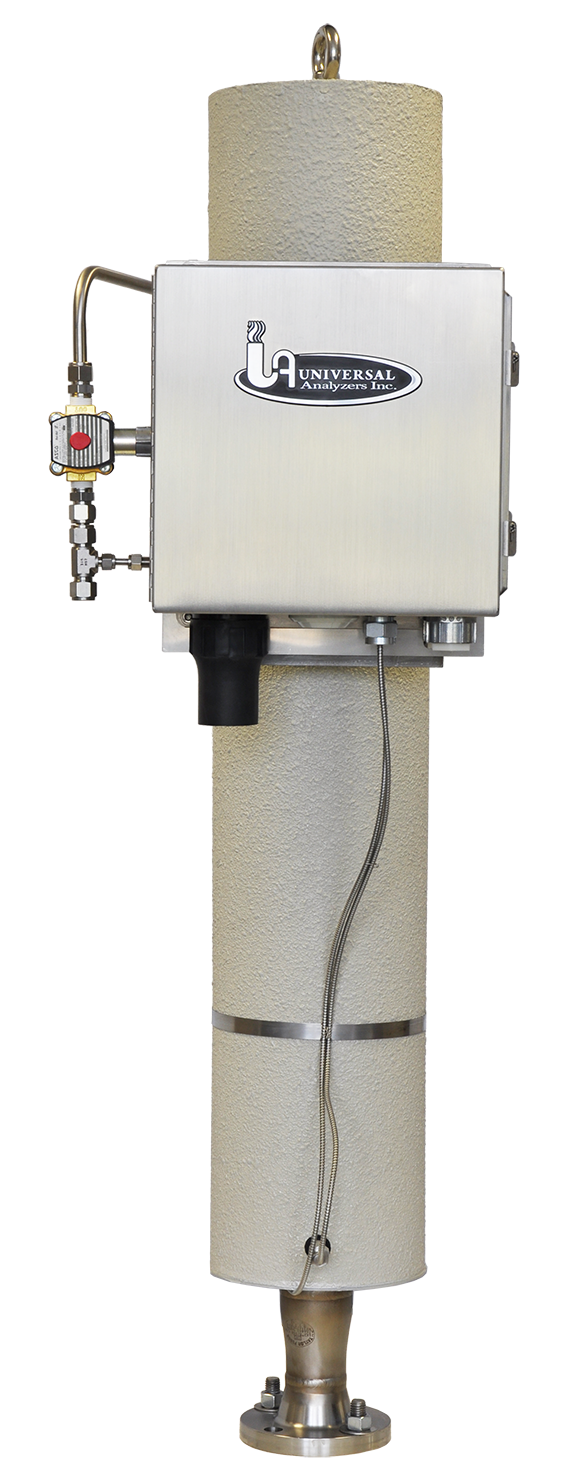

The Universal Analyzers Model 1221 Distillation Sample Probe is a unique self-cleaning and temperature stabilized primary sample conditioning system for demanding on-line gas analysis applications. It is a direct replacement for the Fluid Data Reflux Sampler used for PyGas Sampling.

It is designed to solve the key issues that compromise plant performance by improving measurement accuracy and reliability. The 316SS self-cleaning separator is designed to condense and wash heavy components in the sample back into the process along with any deposited solids avoiding the regular ‘plugging’ that occurs with conventional conditioning systems. Maintenance of the probe is further simplified, as once isolated from the main-line, the separator can be removed without the need to remove the entire probe.

The sample probe uses a multiple-stage cooling design which is made entirely of 316SS. This provides efficient removal of entrained liquids due to its high surface area and thermal efficiency resulting from the unique cooling transfer design utilizing proprietary TraceBoost™ technology.

The high-performance probe design is ideal for use in applications such as ethylene furnaces, FCCUs and coke ovens. The dual vortex cooling system (feed-forward and feed-back control with the electronic control); ensures high-accuracy analyzer performance and protection against liquid carry-over, minimizing the effects of changes in ambient or process temperature. The unique vortex cooling design simultaneously cools the sample and removes particulates, water, and high boiling-point compounds. The electronic controller includes self-diagnostics with local and remote monitoring and displays, configurable fail-safe alarms, and DCS integration, eliminating the need for regular scheduled inspections.

Applications

- Decoke operations

- Fluidized Catalytic Cracking Units (FCCU)

- Ethylene Cracking Furnaces

- Syngas

- PyGas Sampling

Typical Installations

- Decoke headers

- Hot, wet or dirty process gases

- Pyrolysis gases

- Heavy particulate removal

- Fine carbon removal

Features:

- Accurate Temperature outlet gas temperature control (± 1F) with the optional Electronic Controller (EC)

- Dual Pneumatic Controllers available

- Prevents liquid carryover

- Remote monitoring

- Self-cleaning separator

- Reduced maintenance

- Removable one piece 316SS separator

- Automatic sampler shut-down on high inlet temperature or high outlet temperature with optional EC

- High “R” Factor Cooling Chamber

- Probe can be sized to supply 1-5 LPM of Sample

- Suitable for Hazardous Areas

Technical Specifications

- Process contacting parts: 316 SS

- Inlet flange available in most sizes, ratings and specifications

- Weight: 1221 – 150 lbs (68 kg), 1221R – 120 lbs (55 kg)

- Max process pressure and temperature determined by connecting flange specified

- Ambient temperature:

- 32° to 100°F (0 to 38°C) with pneumatic controller

- 32° to 104°F (0 to 40°C) with electronic controller

- Sample outlet: 1/4” Compression Tube Fitting

- Suitable for: Class I, Div. 2, A, B, C, D

- Sample inlet, outlet, and coolant temperature monitoring with the electronic controllers

- Electronic controller data available via Modbus TCP/IP and SD card data logging

- Probe sample gas flow rate: 2 – 5 LPM based on ambient and process conditions

- Sample outlet temperature:

- ± 6°F (± 3°C) with pneumatic controller

- ±2°F (± 1°C) with electronic controller

Supply Requirements

- Electronic Controller: user configurable for 24 VDC or 110/240 VAC 50/60 Hz

- Power Consumption:

- 41W @ 24 VDC (<2A)

- 47W @ 115 or 230 VAC (< 1A)

- Instrument Air (-40°C/F dewpoint)

- 40 scfm @ 80-100 psi (68 m3/hr @ 5.5 – 6.9 bar)

- 80 scfm @ 80-100 psi (134 m3/hr @ 5.5 – 6.9 bar) for dual vortex option