Legacy – Oxygen Analyzer (4401)

Industrial Process Control & Monitoring

- Excellent long term stability and low drift

- Measurement inherently fails high if sensor damaged (no false zero)

- LOD = 0.5 ppm O2 gas phase

- No membranes to foul; No electrolytes to poison; No consumption of O2

- Hazardous area approvals: FM, CSA, ATEX, UL and CE

- No cross-sensitivity or damage caused by: CO2, H2S, NH3, NO2, heavy metals, ethanol, methanol or ionic species pH, S2-, SO42-, Cl-, salinity or turbidity

- Measurement independent of flow velocity

The 4401OXY analyzer optically measures oxygen in either the gas or liquid phase by utilizing quench luminescence of an oxygen specific luminophore.

The analyzer is suitable for direct field installation (NEMA 4X) in hazardous area (Class I, Division 2). The optical fiber sensor platform allows small inline sensors to be installed into sample tubing lines (1/4”), flow cells using NPT fittings, or directly into tanks or process lines using our retractable “hot tap” sensor design. BOS optical oxygen sensors are impervious to typical O2 poisons (H2S) and interferences (combustibles, magnetic, CO2 and H2) with high accuracy and long-term stability measurements without the need for complex or advanced sample conditioning systems. The threaded version of the optical sensor has optional Dual Seal (ANSI/ISA 12.27.01) classification for high pressure applications up to 1200 PSIG (82.7 BAR).

The analyzer display and output units can be setup in either partial pressure (hPa or Torr) or in concentration (ppm or % O2) for the gas phases along with hPa, ppm or ppb for dissolved oxygen in liquid phase.

Typical Applications – Gas Phase (g)

- O2 in hydrocarbon streams

- O2 detection in nitrogen headers

- O2 in process streams

- O2 in nitrogen tank blanketing

- Trace level oxygen in flare gas

- Limit of Detection: 0.5 ppm O2 @ 1atm, 20ºC (0.0005 hPa)

Typical Applications – Liquid Phase (l)

- High pressure produced water Dissolved O2

- ppb dissolved O2 for waterflood injection

- Oxygen in methanol and ethanol

- Oxygen in oils

- Dissolved O2 in liquid process streams

- Dissolved O2 in product streams

Limit of Detection: 1 ppb Dissolved O2

Principle of Operation

The 4401 OXY is a phase fluorometric analyzer that utilizes phase modulation to evaluate the luminescent decay time of an oxygen specific luminophore to calculate oxygen concentration. The sensor has a small luminophore embedded in a polymeric matrix at the end of a fiber optic cable allowing for an extremely sensitive and accurate measurement of the partial pressure of oxygen that is applicable in both gas phase and liquid phase.

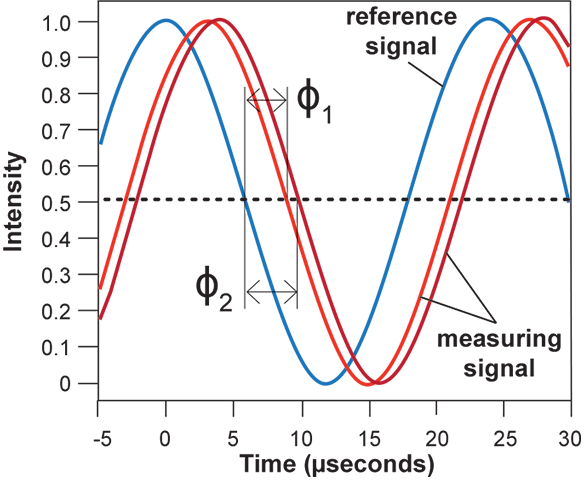

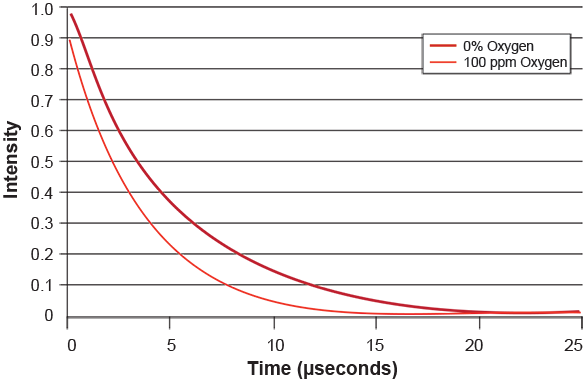

The analyzer uses an LED to emit blue light through fiber optic cable down the sensor tip [Fig 1]. The sensor tip contains the luminophore which absorbs the energy and rises to an excited state. In the absence of oxygen the excited luminophore will fall back to its ground state at a specific rate and in the process emits a red shifted light which is transmitted to the analyzer (spectrometer) via the optic cable where it is detected by a photomultiplier tube. When oxygen is present it quenches the fluorescence at a rate proportional to the oxygen concentration [Fig 2.]. The phase shift between the excitation source and the fluorescent signal is measured and the oxygen concentration is calculated [Fig 3].

Figure 2

Figure 3